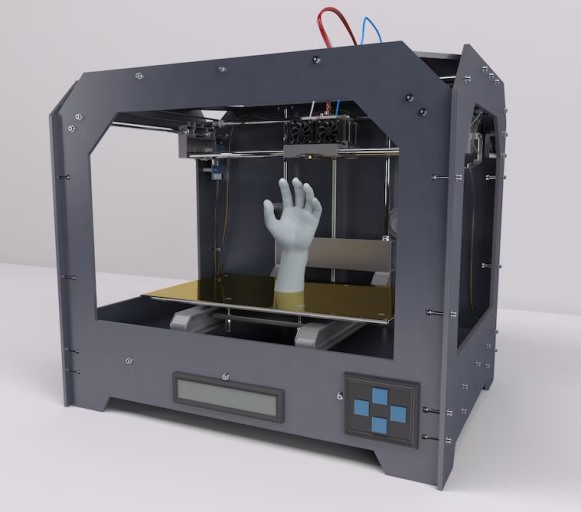

In recent years, 3D printing technology has revolutionized the way we manufacture products. From healthcare to aviation, 3D printing is used in various industries for prototyping, modeling, and production. In this article, we’ll explore the different types of 3D printing technology, their applications, and how they work.

Types of 3D Printing

3D printing, also known as additive manufacturing, is a process of creating physical objects from digital files. Unlike traditional manufacturing, 3D printing allows for complex geometries and customization without the need for expensive tooling or molds. There are several types of 3D printing technology, each with its own strengths and limitations.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is the most popular and widely used 3D printing technology. It works by melting and extruding thermoplastic filaments to create the object layer by layer.

FDM is known for its versatility, ease of use, and low cost. It is commonly used for creating functional parts, prototypes, and models. FDM is compatible with a wide range of materials, including PLA, ABS, PETG, and Nylon.

Stereolithography (SLA)

Stereolithography (SLA) is a 3D printing technology that uses a laser to cure resin into solid parts. It works by exposing a layer of liquid resin to a UV laser, which solidifies the resin into the desired shape.

SLA is known for its high accuracy, speed, and smooth surface finish. It is commonly used for creating small and detailed models, jewelry, dental implants, and medical devices.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a 3D printing technology that uses a laser to sinter powdered materials into solid parts. It works by melting and fusing the powder particles together layer by layer.

SLS is known for its ability to produce parts with high strength, durability, and precision. It is commonly used for creating functional parts, prototypes, and end-use parts for industries such as aerospace, automotive, and medical.

Digital Light Processing (DLP)

Digital Light Processing (DLP) is a 3D printing technology that uses a projector to cure resin into solid parts. It works by projecting a patterned light onto a layer of liquid resin, which solidifies the resin into the desired shape.

DLP is known for its high accuracy, speed, and smooth surface finish. It is commonly used for creating small and detailed models, dental implants, and jewelry.

Binder Jetting (BJ)

Binder Jetting (BJ) is a 3D printing technology that uses a liquid binding agent to bond layers of powder material together to create an object.

BJ is known for its ability to produce large parts quickly and at a low cost. It is commonly used for creating metal parts, sand-casting molds, and architectural models.

AddUp Solutions also provides innovative solutions for Binder Jetting technology, allowing for the production of high-quality metal parts with excellent accuracy and reliability. BJ technology is ideal for creating complex geometries, such as lattice structures and lightweight designs, in industries such as aerospace and automotive.

PolyJet Printing (PJP)

PolyJet Printing (PJP) is a 3D printing technology that uses photopolymerization to create objects. It works by jetting droplets of liquid photopolymer onto a build platform, which are then cured by UV light.

PJP is known for its high accuracy, speed, and ability to produce complex and detailed models. It is commonly used for creating prototypes, dental models, and jewelry.

Direct Energy Deposition (DED)

Direct Energy Deposition (DED) is a 3D printing technology that uses a high-powered laser or electron beam to melt and fuse metal powders or wires together.

DED is known for its ability to produce large, complex, and customized metal parts. It is commonly used in aerospace, automotive, and defense industries for creating engine components, turbine blades, and other high-stress parts.

DED Additive Manufacturing is a process that uses DED technology to create complex and highly customized metal parts. It allows for precise control over the deposition process and the ability to create parts with varying properties and geometries.

Material Jetting (MJ)

Material Jetting (MJ) is a 3D printing technology that uses inkjet printheads to deposit droplets of liquid material onto a build platform. The material is then cured by UV light or heat to form a solid object.

MJ is known for its ability to produce parts with high accuracy, fine details, and multi-material capabilities. It is commonly used for creating prototypes, dental models, and medical devices.

Sheet Lamination (SL)

Sheet Lamination (SL) is a 3D printing technology that uses sheets of material such as paper, plastic, or metal, that are bonded together layer by layer.

SL is known for its ability to produce large parts and complex geometries. It is commonly used for creating architectural models, molds, and other large-scale models.

Laminated Object Manufacturing (LOM)

Laminated Object Manufacturing (LOM) is a 3D printing technology that works by cutting and laminating layers of paper, plastic, or metal to create a 3D object.

LOM is a low-cost and fast 3D printing technology that is commonly used for prototyping and architectural models.

Comparison of 3D Printing Technologies

Each 3D printing technology has its own strengths and limitations, making them suitable for different applications. Here is a comparison of the most common 3D printing technologies:

| Technology | Speed | Resolution | Materials | Cost |

|---|---|---|---|---|

| FDM | Slow | Low | Thermoplastics | Low |

| SLA | Medium | High | Photopolymer resins | Medium |

| SLS | Medium | High | Nylon, metal | High |

| DLP | Fast | High | Photopolymer resins | Medium |

| Binder Jetting | Fast | Low | Sand, metal | Low |

| Material Jetting | Medium | High | Photopolymer | High |

| DED | Slow | Low | Metal powders/wires | High |

| LOM | Fast | Low | Paper, plastic, metal | Low |

Conclusion

In conclusion, 3D printing technology has come a long way since its inception. Today, there are various types of 3D printing technology available, each with its unique features and benefits. From FDM to DED additive manufacturing, 3D printing has revolutionized manufacturing and design across a range of industries.